DiamondX is a new generation of tools for the metal-working industry. DiamondX concentrates a large amount of diamond griton a single layer with an incredibly strong bond. This technology allows DiamondX to cut and grind materials that traditional diamond tools could not.

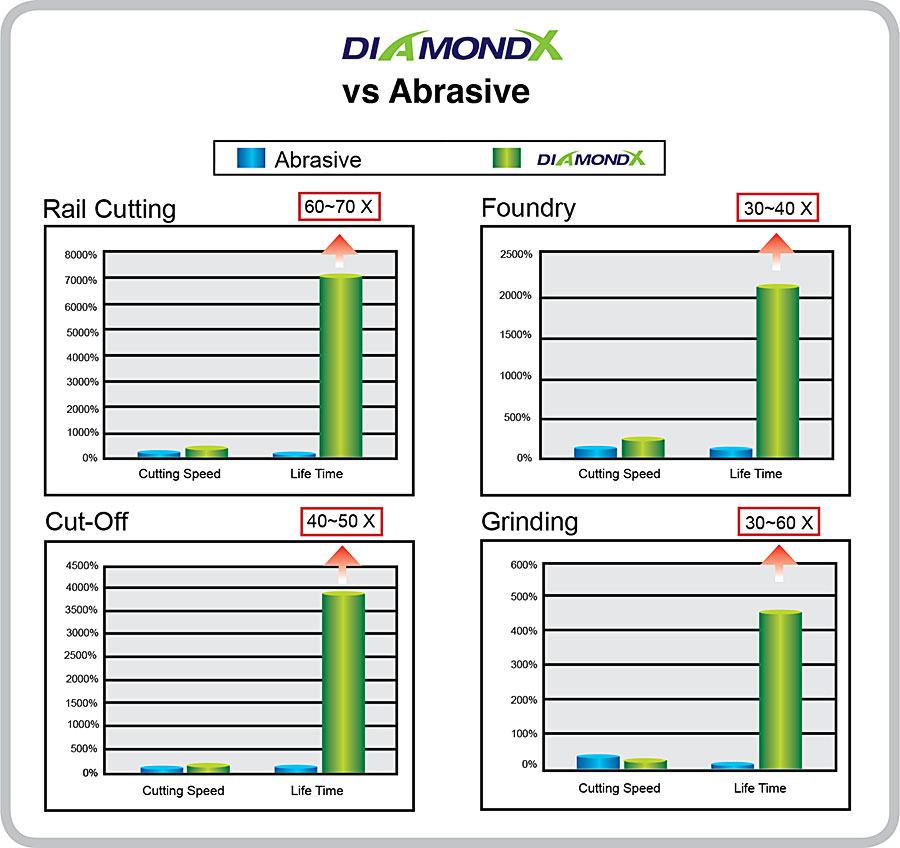

DiamondX is made with diamonds, the hardest natural material known to mankind. It is manufactured by a unique brazing technology that allows a high concentration of diamonds to be chemically and mechanically bonded to a steel surface. The resulting tool life is far greater than standard abrasives such as aluminum oxide, zirconia alumina or silicon carbide.

DiamondX can cut and grind an extremely wide range of materials such as:

- High and Low Carbon Steel

- Hard Facing Alloys

- Ductile Iron

- Cast Iron

- Rail Track Steel Section Bar & Tube

- Wood, Plastic, FRP & PVC Ceramic

Benefits over Conventional Abrasives

- DiamondX delivers cost efficiency with longer tool life

- Less downtime changing worn abrasives discs

- Reduced sparks, less debris and no odor

- Wheel breakage eliminated

- No reduction in tool size or shape

- A wide variety of tools for cutting, grinding, weld joint removal, forming, and surface prep work

- The same tool can be used on ferrous and non-ferrous metals as well as ceramics and polymers