Supreme grade, silent core blades for hard materials. The 925DSLX are cost effective diamond blades with an epoxy filled pattern cut in the core. Laser Cut Cores achieve a reduction of 4 dB(A) compared to standard diamond blades. Reduction in sound level provides lower vibration that will increase tool life. Medium bond for less abrasive material.

| Diameter | Width | Arbor | Part # | |

| 14" | (356mm) | .125" | 1" | 161283 |

| 20" | (508mm) | .145" | 1" | 160971 |

| 24" | (610mm) | .142" | 1" | 168050 |

| Segment Height | 10mm | |||

Silent Core Blades

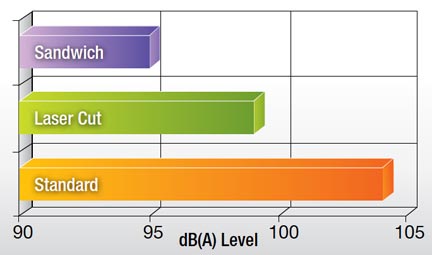

Silent Core diamond blades have a specialized core that reduces vibration and noise. Instead of the standard high-pitched whine, Silent Core blades are significantly quieter. This is beneficial on job-sites where controlling the cutting noise level is an issue and a quieter blade reduces the chance of hearing loss for the operator. Silent Core blades have two designs. The Laser Cut Core has epoxy filled silencing material that provides limited noise reduction/suppression. The Sandwich Core is manufactured with two steel cores laminated with a copper center that provides the greatest sound reduction.

Core Styles

A reduction in dB(A) of 10 will reduce human noise perception by

approximately

one

half. Noise reduction depends on a number of factors.

Laser Cut Core Design

Cost effective laser cut core with epoxy filled silencing

material,

provides limited noise reduction/suppression.

Sandwich Laminated Silent Core Design

Sandwich laminated steel cores with copper

center

provide

the greatest sound reduction.